The University of Minnesota’s Office of Classroom Management employs dozens of student employees to help maintain learning spaces across campus. (Check out our articles on How the UMN Office of Classroom Management Skyrocketed Classroom Readiness from 41% to 95% and How UMN Empowers Student Employees to Do QC Inspections Across Campus for the full story.)

This is the final piece in our series on the OCM’s success story, and we’re going to drill deep into how the team trains students to be effective.

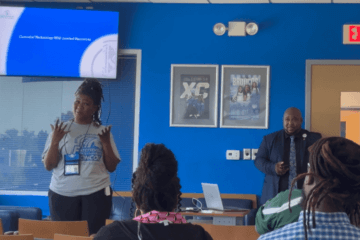

In a presentation at the 2019 MAPPA conference, project manager Jessica McCarty outlined how the office revamped their training program for student employees. Because there are new student employees every semester, as people drop in and out based on their schedules or graduation, they’ve been able to refine the process over time.

So how does the team train new classroom condition monitors?

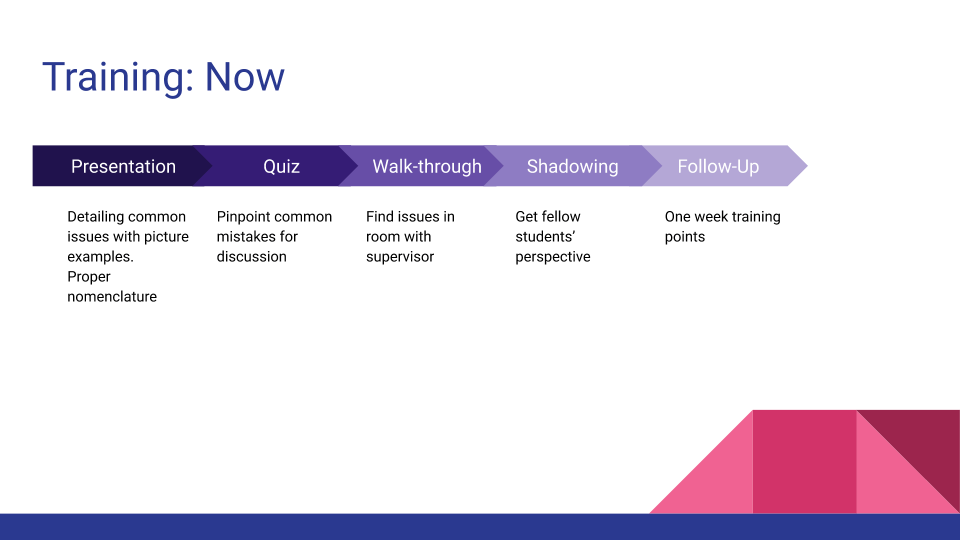

Step 1: An online presentation at the student’s own pace

“There was a content-heavy, text-heavy packet of paper that [the OCM] used for training,” Jessica says. “We took all of that information, and we actually moved it over into a Google Slides presentation that detailed common issues with a lot of picture examples. We gave them a lot of examples of how we want things phrased, the proper terminology.”

She says the simple swap from a bulky packet of paper to Google slides has had “a lot of significant benefits,” including:

- Easier editing. Rather than wrestling with a hard-to-format document blending text and pictures in Word, the team can now make simple edits to the Google Slides presentation. The edits are live immediately and don’t require the whole document to be printed out again.

Because it’s easier, the team updates the presentation frequently. That means each new employee is seeing the most up-to-date information. - Less work for supervisors. “Before, they had a packet of paper, they talked at the student for two hours, and the supervisor had to be there the entire time,” Jessica says. “Now, we have them in the office with us, but they’re going through that presentation while the supervisor’s still in the room. It frees up that first hour for them to continue to work on other tasks while the student is going through the presentation, so it made their day a little bit more efficient.”

- Better training for students. This is the biggest benefit the team has seen. “Instead of being talked at for two hours, [students] got to pace their own learning,” Jessica says. “We give them this presentation; we don’t tell them how long they have to complete it. They have that full two hours of training if they want it. They can go back a few slides to review something if a future slide triggered a question and they want to go back and review it. If they’re catching on really fast, they can go through slides at a faster pace. The pace was no longer dictated by the supervisor; it was dictated by the student themselves, which really helped with retention.”

Step 2: A quiz covering common points of confusion

Next, the team added a quiz to the end of the presentation. They had found that students were making the same mistakes in their initial inspections after training. Therefore, they created questions that would cover those issues early, while the supervisor was still on hand.

“It really pinpointed those common mistakes for discussion in training — again, trying to smooth over those points of confusion early on, so students didn’t have to discover it for themselves out in the field.”

Step 3: Walking through the process together

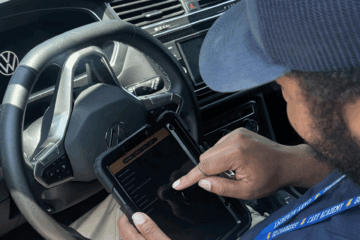

After the student goes through the presentation and takes the quiz, the supervisor gives them a quick tour of the office. Then, they grab an iPad with OrangeQC inspection software and go out to a classroom with the student.

“That allows us to be in a room with them and that software, to walk through all the different points, give them our perspective on how we’re seeing the room, and what we would report if we were in that room,” Jessica says. “They have a better idea of our expectations and the level of detail we’re asking for them up front.”

Step 4: Trying it solo, then shadowing

“After that, we let them do inspections for a day on their own, and then we offer up the opportunity to have them shadow a student who has been around for a little bit,” she continues. “By giving them that day alone, it lets them stumble across some of these points of confusion on their own, so they can come prepared to their shadowing experience with a list of questions. It also gives them a chance to ask those questions in a more informal setting, with a coworker, not a supervisor.”

Step 5: Reviewing progress together

Finally, the student starts performing inspections — but it’s not the end of the training process.

After the student has been performing inspections for a full week, the OCM team reviews their work.

“We comb through all of their inspections, pull out some points for training notes and some points for positive feedback, send it over to the student and just check in with them,” Jessica says. “How are inspections going? Are there any lingering questions? Here’s our feedback for you; do you want to meet in person to talk about it?”

That check-in helps close the loop on the training process and ensure the student is on the right track.

The end result: Better training = better employees

Jessica says that the value of the new training program has been obvious.

“By breaking out training into these multiple steps, it really helped them with retention and comprehension of the material,” she says. “We really saw that improved the initial quality of inspections compared to the previous training experience.”

We think that the OCM’s training process is inspirational for many types of teams. For your own organization, you might want to consider:

- Do our training materials stay up-to-date when there are changes? Are they easy to edit, or is it a chore?

- What common points of confusion come up for employees? What things can you get ahead of?

- Does the employee being trained have the chance to ask questions? Do you check in with them throughout the process, including after they’ve started on the job, or are they thrown into the deep end?

Thanks again to Nick Pnewski and Jessica McCarty for sharing the OCM’s story. We think it’s incredibly valuable for teams in education, as well as those outside higher ed.

If you’re looking for more resources, check out all of our educational facilities articles, including how to use APPA quality inspections on campus.