Kelly Freshcorn knows how to make the most of limited resources. She’s worked on recycling at the University of North Carolina at Charlotte for 25+ years, starting as a student worker, and has a reputation for thinking creatively to maximize her team’s impact.

At the NCAPPA 2025 conference for educational facilities, she presented on how UNC Charlotte’s recycling team is using OrangeQC. During her presentation, Freshcorn shared three critical projects her team is taking on to save money, cut down on waste, and recycle more materials.

We loved her presentation and caught up with her after the show to hear more about how digital inspections have revealed valuable insights for her team.

Asking the right questions for continual improvement

Recently, Freshcorn stepped into the role Recycling and Universal Waste Operations Manager. At the same time, new leadership started asking what her team would want in order to take their processes to the next level.

That was music to Freshcorn’s ears.

“As a recycler, you’re usually at the bottom of the food chain when you have a small budget to start with,” Freshcorn said. “When the one-time funding comes out, there’s always bigger things that people have to worry about.”

The larger UNC Charlotte team facilities team had recently started using OrangeQC to improve operations by running inspections for custodial staff, following up on special projects, and more.

So when Freshcorn mentioned that she wanted to start doing employee spot checks to Solomon Franklin, the facility team’s Chief Experience Officer and Director of Business Operations and Quality Assurance, he put her in touch with teams already using digital inspections.

From smart questions to valuable data

In less than six months of using OrangeQC, Freshcorn created three separate projects that use digital inspections to yield valuable information for her team.

For each project, she started by asking: What do we want to know? What questions do we want answered?

From there, she worked with the operations team to create mobile inspection forms designed to capture that information and created a plan to capture high-quality information. (And because this is recycling, sometimes that plan involved climbing up on dumpsters and startling racoons.)

The team analyzes the results to bring high-quality data into the decision-making process.

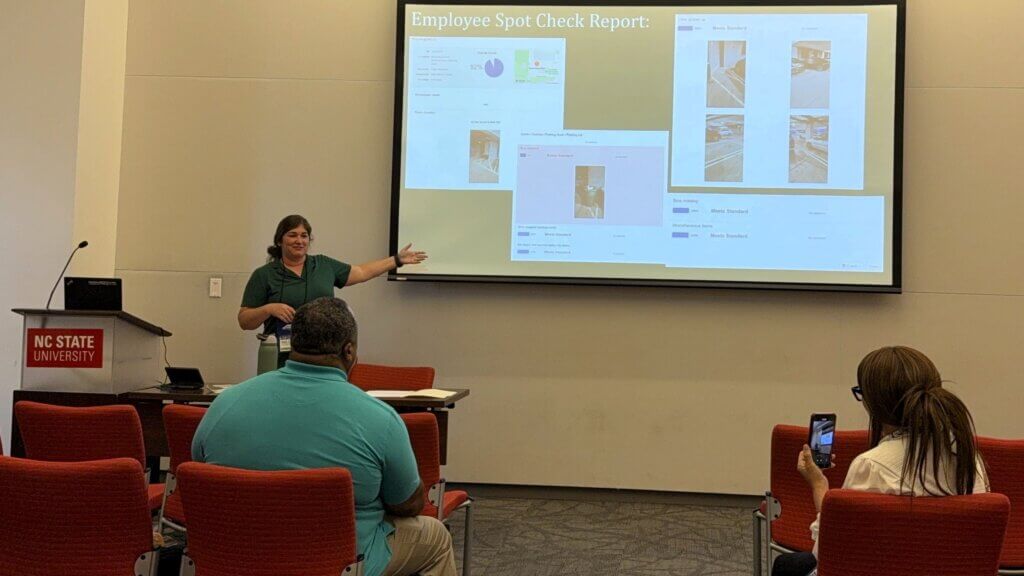

Inspection Project 1: Employee spot checks

The first project Freshcorn kicked off is a spot check program for her staff. She wanted to know: How is the staff performing? What are areas of improvement for individual staff members?

Freshcorn created the inspection form based on a list of standards she’d outlined for her team. By using familiar standards, she’s inspecting what she expects on a day-to-day basis.

For the UNC Charlotte recycling team, these standards are:

- Bins should be emptied regularly. If the bin is half full or more, it should always be pulled. If it’s less than half full, it’s up to the technician’s discretion.

- Bins and lids should be clean. According to Freshcorn, research has found that people are more likely to use clean bins.

- Paper bins should not have a plastic liner. Freshcorn says that while some people on her team tend to use liners in paper recycling bins, the best practice is to leave them out, which cuts down on waste. (These bins have a small trash slot that things like beverage cups won’t fit into, which helps prevent liquid contamination.)

- Can liners should be tied appropriately. The liners should be tied for a neat appearance and to keep them in place. Cans should not have “skirts” with the plastic coming out of the lid.

- Bin labels need to face outward. Freshcorn said that labels need to be visible as someone is approaching the can. Recently, her team has switched to putting labels on all four sides of the cans so that the label is readable from every direction.

- Bins must be in the correct order. The bins are arranged with trash and paper on either end of the recycling container. This helps reduce splatter from drinks thrown in the trash.

- Missing bins have been reported. “Bins have legs,” Freshcorn said. If one’s gone missing, her team needs to notify her so she can track it down.

- Parking deck responsibilities are handled. The technicians on Freshcorn’s team are currently also responsible for a parking deck on campus. For this area, litter must be picked up, and the stairwells, elevators, and bathroom must be clean.

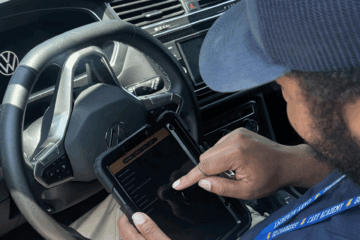

For each inspection, supervisors take a photo of the general area, which helps ensure they’ve got the right location. Then, they rate each line item as meeting standards, needing attention, or being below standards.

“And then you hit submit, it goes into the system, you go back to your office, and you have the whole report,” Freshcorn said. “If you have a deficiency, you go find out what’s going on.”

Freshcorn aims for a score of 95% for her team. Most of them are meeting that goal. For the ones who aren’t, she’s now got scores and photos to review to help get them up to that goal.

Inspection Project 2: Dumpster survey

The second project Freshcorn tackled may have some big implications for the future of waste management at UNC Charlotte.

“We’ve been talking about hauling our own waste at UNC Charlotte for a while,” she said. That would be a big change — and the team needed to know just how much waste they were dealing with. “So we’re talking about, what is in the dumpsters? How do we know if we can handle all the garbage?”

Freshcorn started with a list of questions her team would need to investigate. She wanted to know:

- How much trash is in the dumpsters?

- Is there any recycling in the trash dumpsters?

- How much cardboard is in the cardboard dumpsters?

- Is there any trash in the cardboard dumpsters?

- Has the dumpster been picked up?

Freshcorn worked with office staff to create a form to capture all of the information above. Then, she set out to inspect and photograph the contents of all 100+ dumpsters on campus.

When she analyzed the results, it was obvious that many of the dumpsters were not being used much. She learned that they could reduce service to several dumpsters, and potentially eliminate two of them entirely.

“OrangeQC did the trick,” Freshcorn said. “We got a lot of information in two short weeks.”

In the long-term, the survey’s results might lead to a pilot program where they test out in-house waste hauling. But more immediately, they are learning where they can cut down on service to save money without impacting service on campus.

Inspection Project 3: Parking deck bin usage survey

The last example Freshcorn shared is a survey that measures parking deck bin usage and litter.

The office kept getting complaints that the staff wasn’t emptying the bins at one of the decks, causing litter to be left on the ground. Freshcorn knew that her team was emptying the bins — but she needed data to prove it, and to reveal the real problem.

Once again, she started with the questions she wanted answers to. In this case:

- How much trash is in the bins?

- How much litter is on the parking deck?

To get that data, Freshcorn created a form to inspect each level of the parking deck. She took photos and documented how full the bins were, on a scale of 1 to 5, as well as how littered the parking decks were.

Then, she got her steps in.

Freshcorn went to every floor of the parking deck, documenting the fill level of each bin and the amount of litter on the ground.

Then, she analyzed the data, which showed that her team was on top of both the bins and the litter. The problem was that the level of service couldn’t keep up with people leaving trash everywhere, even right next to empty bins.

She was able to take that data to the people who were upset that the job wasn’t getting done. That opened up a conversation about what could be done to address the issue, since her team was already fulfilling the terms of its service level agreement.

The survey helps the team continue to measure conditions at the parking decks, regularly checking in on changing conditions.

Conclusion

Freshcorn has been making the most of her department’s resources to run a smarter, more efficient operation. She’s asking good questions, creating ways to test them, and using the data to create a plan to move forward.

She said that OrangeQC has been a very useful tool for that process.

“You have your timestamp, your picture, and however you want to quantify what you’re measuring,” she told us. “When OrangeQC landed in my lap, I said, ‘I can use this. This will work great.’”

Want to see how OrangeQC can give your team the information it needs to run more efficiently? Schedule a one-on-one demo to see the tools in action.