Judy Gillies is the president of The Surge Group, a cleaning consulting company in Toronto. She’s a CPA who has found the jump from finance to janitorial a natural fit.

“Cleaning is a lot about numbers,” she says. When businesses ignore that, they do so at their own peril.

Today, The Surge Group runs third-party audits to help companies and organizations find out what’s working (and what isn’t) with their cleaning programs.

We recently caught up to find out what trends she sees within the cleaning industry, how small companies can level the playing field, and the biggest mistake she sees janitorial teams make.

OrangeQC CEO Matt Gornick chats with Surge Group president Judy Gillies at ISSA Show North America.

Here are six of the top tips Judy shared to help teams optimize their performance and boost business relationships.

6. Get on the same page.

Bringing in an outside set of eyes or taking time to review the cleaning contract can help catch things that are falling between the cracks.

Judy once worked with a hospital that had a mix-up on who was cleaning what. One department thought a specific line item was being cleaned by another department; that department thought someone else was, too.

“It turns out nobody was cleaning it,” she says. “And that’s what the audit reveals.”

Of course, in a hospital environment, something going uncleaned could be disastrous. But all cleaning teams can benefit from having clarity on what they’re responsible for . . . and making sure their client or organization understands that, too.

(We recently wrote about PR reports, which create a great opportunity for janitorial teams to go over line items, cleaning quality, and other responsibilities with their clients. They’re our number one recommendation for ensuring everyone’s on the same page.)

5. Doing APPA? Be consistent.

One of the top questions Judy gets is how to convert APPA ratings (developed by the APPA organization and commonly used at educational facilities) to percentages.

“APPA audits are very popular,” she says. “But APPA is harder to understand outside of facilities.”

Because of that, most teams convert the 1 to 5 APPA rating to a percentage, which is an easier way to discuss results. However, the APPA organization does not prescribe a formal conversion of APPA Cleaning Standards to percentage scores. “That’s where there may be a gap,” she says.

While Judy has calculated her own recommended conversion and best practice, she says the bottom line is to be consistent within your own organization. That way, you’ll be able to compare items at a glance.

(On the same note, if you’re comparing scores with a different organization, be mindful that they may not be using the same conversion.)

4. Celebrate the good.

One thing Judy sees many teams miss? “Inspections need to be positive, as well,” she says.

She sees cleaners embracing inspections when their hard work is finally noticed — sometimes for the first time. That recognition can help improve cleaning quality, boost morale, and even improve cleaner retention; we all want to have our hard work noticed, after all.

That’s why it’s important for teams to celebrate the good results they see from quality control programs. Let people know when they’re doing a good job. Don’t just scrutinize the faults; look at the big picture and praise what’s being done well.

3. Use technology to level the playing field.

Judy has been a long-time fan of OrangeQC (and we’re fans of hers!) for the way it “brings cleaning companies equal abilities to provide audits.”

“It levels out the playing field,” she says. “OrangeQC provides a pretty low rate to get in on an inspection system for one or two people. A small contractor can be just as competitive in quality control as a big, large organization.”

That’s because it’s common for large companies to use technology to improve efficiency, boost cleaning quality, and communicate with their customers. They’re willing to pay and invest in those solutions for two reasons. First, it’s the only way they can reliably get things done with a huge organization. Two, it allows them to service increasingly larger customers.

In the past, only big cleaning companies could really offer these types of solutions to their customers. Companies like OrangeQC have opened up the possibility for smaller teams to provide similar value-adds to their customers.

It’s not just OrangeQC, either. There’s a lot of technology out there that can help small teams perform on the same level as big teams. Professional-level reports, automatically generated dashboards, and more help showcase your team’s performance no matter its size.

2. Actually use your data.

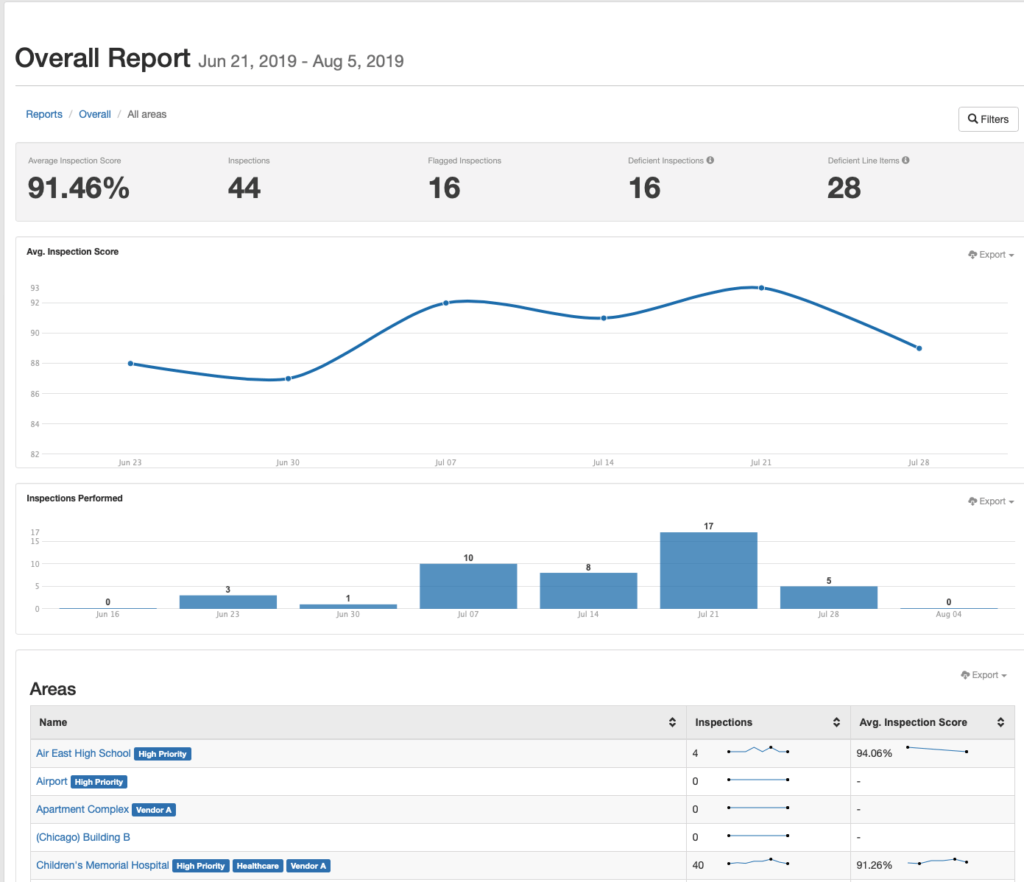

Judy says the biggest mistake she sees cleaning companies and facilities teams make is failing to actually use the data they collect. They might do inspections and audits, but they don’t fix the problems that arise.

“They won’t reallocate labor, they don’t go enough into the information to figure out what it means,” she says. And then, nothing changes.

Instead, she says teams need to ask a basic question: “What is it we need to do to stop this problem from recurring?” That might mean training staff, or reallocating resources to a washroom that’s seeing more usage, or going back to the client and letting them know you need more resources to tackle something.

1. Brag a little bit.

Judy says contractors need to be proactive about communicating with their clients, especially when things are going well.

“Some of the contractors do a great job, and the client doesn’t even know that they’re doing well, because there’s no stat on it.”

Inspections results and audits can be a great conversation-starter in this arena. Judy says most organizations appreciate a top-level report or dashboard that shows off the big picture: how many audits are being done, how the team is performing, and whether deficiencies are being corrected.

Her pet peeve? “Some people just give clients the login [to inspection software],” she says, and then never follow up to give the client data, instead expecting that their clients will just log in and check if they’re curious. “That’s really insufficient. If you don’t have enough time, why would your client have enough time?”

She says sharing a snapshot of how things are going, monitoring quality over a certain period of time, or even “some bragging” are all great ways for cleaning and facilities teams to keep open lines of communication with their clients.

And if something isn’t going well? Fess up. Judy says that admitting when something has gotten missed can help build trust and a sense of transparency — especially if you follow up and demonstrate that you’re committed to addressing the problem.

A big thanks to Judy Gillies for taking the time to share her insights! We hope they help your team create a quality control program that works for you.