Welcome to the third part of our Quality Control 101 series! In our previous two articles, we explored why it’s important to track quality through inspections and how to create your own inspections. Today, we’ll look at who performs the inspections.

We’ve outlined four key steps to making sure your inspectors (whether that’s you or your employees) do a great job.

1. Decide who’s owning inspections.

If you’re the owner of a smaller company, you’ll probably handle this role. But since we’re trying to build a quality control system that can scale as you grow, eventually, this role should be able to be taken over by a manager or supervisor, or several managers.

If you have people who supervise the members of your cleaning teams, they should perform the inspections.

Decide who will handle which inspections and communicate that information to your team. Make everyone knows you consider inspections a priority — which brings us to our next point.

2. Set aside time to get inspections done.

The important thing is that whoever is performing inspections needs to have time to actually do the inspections. It sounds obvious, but it’s absolutely crucial. The QC system will fall apart if you don’t have anyone doing the basic step of performing inspections to track quality.

Doing an inspection may not feel like the most urgent task on your plate on any given day, but it will always be one of the most important. (Check out our article on the Eisenhower Box for more insight on the tension between urgency and importance.)

Scheduling out the inspections you want completed will help keep everyone on the same page and determine whether your expectations are realistic. Which leads us to the next step . . .

3. Decide how often to inspect.

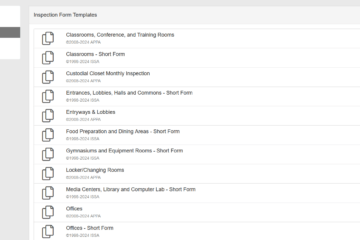

The time spent on inspections and the number of inspections performed each week will vary depending on your company. A good rule of thumb is to walk through your smaller accounts at least once or twice a month. During each walkthrough, you might perform five or ten inspections for the various area types at that location.

For your more valuable accounts, you will want to be in that facility tracking your performance on a weekly basis.

If your team isn’t performing inspections often enough, then the only way you’ll hear about poor performance will be from your customer. That’s a costly way to learn your QC process isn’t working.

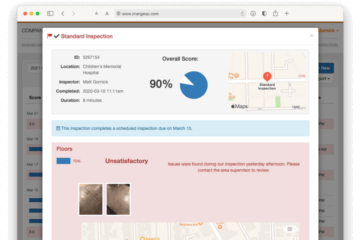

So sit down and schedule out your inspections. Then, follow up and make sure they get done. You can put the dates on a shared calendar, or automatically schedule and assign the inspections through a dedicated janitorial inspection app like OrangeQC.

4. Make sure your team is on the same page.

Your inspections are only going to mean something if you’re consistent. You need to make sure you rate everything the same way today as you will two weeks from now. And when you’re training others, they need to be able to do the same thing.

When you hire or promote a manager to perform inspections, it’s key to do the first few inspections alongside them. This will help ensure ratings are consistent across your team.

Those are the four keys to setting your inspectors up for success! Remember, your QC process will only be as strong as your weakest link. Make sure that your managers are well trained and have the time to do inspections.

Once you start tracking your quality, you can begin to be proactive about fixing issues. In our next article, we’ll talk about how you can leverage your improved cleaning quality (and all the stats you have to prove it) to grow your business with new customers.

Next up, find out how to leverage your quality control program to win (and retain) more business.