Environment Control Tucson prides itself on built-in accountability, radical transparency, and meticulously tracked communication. They’ve built a reputation for keeping a close eye on cleaning quality — and being responsive to client concerns.

“I would even call it more than quality control,” president Brandon Ingram says about the company’s approach. “It’s really accountability to our customers.”

Ingram spoke with us recently to chat more about how the team embraces accountability, as well as the payoffs they’ve seen in the form of attracting new customers and retaining their current ones. We’re excited to share how their process integrates quality control from beginning to end.

Case study: Environment Control Tucson

Environment Control Tucson is a janitorial, landscape, and facility services company that has been in business for about 40 years. As of 2023, they employ about 150 full-time and part-time employees, who work together to service 2 million square feet and 25 acres a day.

EC Tucson’s client portfolio runs the gamut from small doctor’s offices to manufacturing facilities – even a power plant.

Ingram has been helping out with the business since he was a teenager. “I’ve done every position from stocking chemicals and repairing vacuums to special services and sales.” He says that this firsthand experience has been incredibly helpful to him as general manager, giving him the perspective he needs to explain why the team operates the way it does.

Quality Control Along The Client Journey

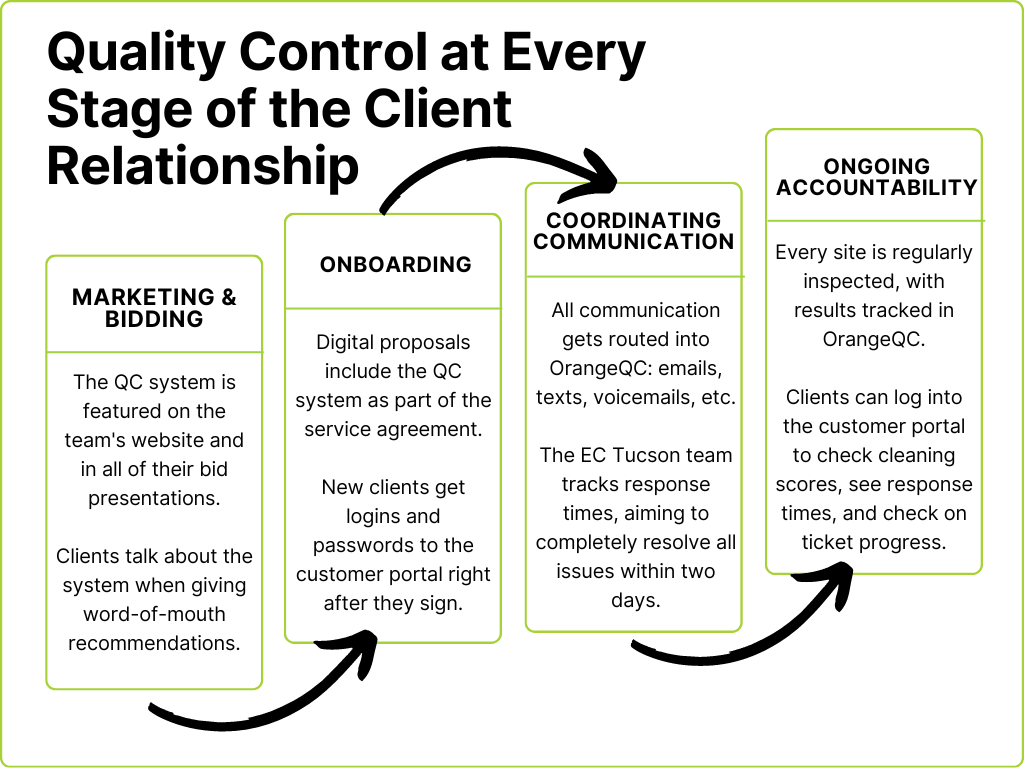

Environment Control Tucson strategically integrates quality control into every aspect of their client relationships. This flowchart gives a high-level overview of that process:

We’re going to dive deeper into each stage of the relationship to highlight the best practices that the Environment Control Tucson team uses. These strategies allow them to keep a close eye on quality and deliver better service to customers.

1. Before Signing: Marketing, Bidding, and Word-of-Mouth Recommendations

EC Tucson’s focus on quality control starts before clients have even inked the contract.

“We present our solution when we’re just talking about our services,” Ingram says. “OrangeQC is presented as one of the aspects of who we are. It’s in our presentations, and the customer hears about it from the beginning.”

This focus on quality control even extends to word-of-mouth recommendations. The ease of contacting the team, alongside the visibility of checking inspection results, is a popular feature with their clients — and those clients spread the word.

“We actually hear it all the time,” Ingram says. “We get other property managers saying, ‘Hey, EC is the company you want to go with,’ and it’s because of the system.”

2. At Signing: Onboarding New Clients Into the System

Environment Control Tucson asks new clients provide the names and email addresses of everyone who needs access to the customer portal at the same time as they sign the digital proposal.

Immediately after the proposal is signed, the team generates logins and passwords and sends them out.

This means that the system for communication and accountability is in place from Day One. Clients know where to go with questions, concerns, and problems. This also allows the Environment Control Tucson team to deal with everything in one place, as we’ll talk about next.

3. Existing Customers: Coordinating Communication in One Central Location

“Any way a customer can get ahold of us automatically gets routed into OrangeQC, into tickets,” Ingram says. That includes emails, text messages, and even voicemails.

By collecting all of that customer communication in one central location, the EC team is able to address issues efficiently. They can view, assign, and respond to issues in one spot.

Analyzing that data helped EC Tucson find one particular opportunity to improve. OrangeQC’s ticket system tracks how long tickets go unresolved. Turnaround on a ticket used to take about a week, but the team decided that wasn’t good enough — especially, Ingram says, when it “shouldn’t have looked bad in the first place.”

Now, every deficient score generates a ticket. The team aims to resolve each of those tickets completely within two days at the latest.

That quickness was inspired in part by Amazon. Ingram reasoned that in a world where the online retailer can get a package to your door from across the world in two days, surely customers expected just as timely a response from their janitorial, facilities, or landscaping contractor.

That’s just one example of how staying on top of the quality control data and trends gives the Environment Control Tucson team early insight into problems and opportunities.

4. Maintaining the Client Relationship: Regular Inspections and Reports

Every account gets inspected at least twice a month: once by the supervisor, and once by the operations manager. If inspections come in with deficiencies, it automatically creates a ticket. This helps make deficiencies visible so that the team can make corrections and bring cleaning quality up.

“OrangeQC allowed us to be accountable,” Ingram says. “We were already doing inspections, but this was removing the process of having to have paper. Now, I can get it into your hands quicker. You can see I was there, you can see the GPS location of where I was.”

The technology they use may have changed, but the inspection process itself has been remarkably consistent. Before digital inspections, the EC Tucson team would fill out inspections on carbon copy paper, then tear off copies for the customer, the employee, and the main office to follow up on.

“We were doing OrangeQC on paper before OrangeQC was a thing,” Ingram jokes.

Rather than inventing the quality control process from scratch, the team used digital inspections to supercharge the process that was already delivering solid results for their clients, employees, and central office.

The importance of accountability

Ingram has seen a real hunger for the kind of transparency and accountability his team is offering. In fact, some of their clients have included a requirement for a digital inspections and quality control program into their new requests for proposals after working with EC Tucson.

“They all want reports, they want to make sure that you were there and did what you said you were going to do,” Ingram says. By loading all of the data into a quality control system, EC Tucson empowers its clients to look into the quality control data whenever they like. “It’s all just there. You log in and see what you want to see.

According to Ingram, there’s no real downside to sharing this kind of information with clients — if the team is doing its job well, then strengthening communication just helps make sure everything is on track.

“When other people aren’t eager to have [clients] on the system, we see it as a lack of wanting to be accountable . . . it just makes everybody’s job better and easier.”

In Conclusion

We love working with Environment Control Tucson and seeing how they’ve embraced digital solutions to empower radically transparent quality control. Thanks so much to Brandon Ingram for taking the time to share more about your team’s philosophy!

Not using OrangeQC to transform your quality control system and impress your customers? Schedule a one-on-one demo so we can learn more about your team’s needs and show you the tools that can help.